call1911

Member

- Joined

- Apr 15, 2020

- Messages

- 135

Hi all!

I couldn't find anything here in regard to my question.

In case I should have missed it, please be patient with an old man.

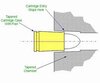

Right now it's about 9mm Para ammo but it would be also a matter for other straight wall pistol cartridges.

Imagine the following - you prep a cartridge the usual way.

You

1) expand the case for a bullet

2) fill the case and

3) seat the bullet

Now usually the doctrinal opinion is that you

4) apply just the right amount of taper crimp to remove the belling of the case.

But what if I do NOT taper crimp and the cartridge nevertheless fits in my case gauge easily and also passes the plunk test?

What could be the necessity of a taper crimp?

Why would I add this step?

My knowledge: Bullet tension comes from the straight part inside the case and not the taper crimp.

If I use FMJ bullets there is not much danger to "strangle" the bullet but with a plated bullet this happens easily when applying a taper crimp.

So it seems there can be done much wrong for what purpose?

Or: if I expand so little that the cartridge passes the plunkt test - is the case too little expanded?

Curious about your opinion/knowledge!

Bye!

I couldn't find anything here in regard to my question.

In case I should have missed it, please be patient with an old man.

Right now it's about 9mm Para ammo but it would be also a matter for other straight wall pistol cartridges.

Imagine the following - you prep a cartridge the usual way.

You

1) expand the case for a bullet

2) fill the case and

3) seat the bullet

Now usually the doctrinal opinion is that you

4) apply just the right amount of taper crimp to remove the belling of the case.

But what if I do NOT taper crimp and the cartridge nevertheless fits in my case gauge easily and also passes the plunk test?

What could be the necessity of a taper crimp?

Why would I add this step?

My knowledge: Bullet tension comes from the straight part inside the case and not the taper crimp.

If I use FMJ bullets there is not much danger to "strangle" the bullet but with a plated bullet this happens easily when applying a taper crimp.

So it seems there can be done much wrong for what purpose?

Or: if I expand so little that the cartridge passes the plunkt test - is the case too little expanded?

Curious about your opinion/knowledge!

Bye!