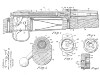

I don't have a bolt face picture of my Mauser M71-84, but all the old Mauser actions were push feed.

View attachment 1000137

That is till the 1893-94 actions were Mauser made the actions controlled feed to prevent double feeding. The military extractor was designed to feed from the magazine only! The true Mauser military extractor is not beveled at the bottom, such as the commercial M98 extractors, there is a slight rounding at the bottom of the extractor to allow the extractor to snap over a cartridge rim

View attachment 1000138

Ruger removed a lot of material so the extractor would snap over a round in the chamber

View attachment 1000139

I think this is the magazine only feed, military Mauser extractor

View attachment 1000140

I don't have many feed from the magazine only extractors, because I have had issues, during rapid fire, where the round popped out in front of the bolt face, and I could not close the bolt. This will cause an alibi in competition, as I could not pluck the round out of the chamber with a fingernail. I had to break position, bang the rifle butt on the ground, to extract the round. What I have done with feed from the magazine only extractors, is bevel/round the bottom with a dremel tool till the bolt closes on a round in the chamber.

Some shooters don't understand the military Mauser extractor, will put a round in the chamber, and then try to close the bolt, and find they can't.

this Mauser extractor was picked up at the range, tossed on the ground behind the firing line.

View attachment 1000141

View attachment 1000142

We all puzzled about what could have caused this, and I think the best explanation is that the rifle had a military extractor, one that would not snap over the rim or a round in the chamber. The shooter just beat the bolt handle down until the extractor hook broke off the extractor body. As you can see the extractor is bowed. And, once the hook had broken, probably just bent the back of the extractor pulling the extractor body off the bolt.

The pre 64 is a controlled round feed, but it was designed so a round could be put into the chamber, and the bolt closed over it.

View attachment 1000143

You can see that the extractor is heavily beveled, however, I recommend always feeding from the magazine. If you force the extractor to snap over the rim, in time, the extractor will break.

This is a continuing problem with the early "pseudo" controlled round feed Ruger M77's.

You would never have known it from the advertising of the age, but when these rifles were introduced on the market, the claw extractor was only there to give the rifle the appearance of a classic Mauser action. At the time, I remember the chorus of gunwriters singing the praises of the "Mauser" like extractor,

how wonderful, how perfect!

View attachment 1000144

This is a push feed extractor, this is not a controlled round feed extractor. And there is nothing you can do to make it a controlled round feed. This extractor snaps over the rim, and the real problem is, in time the extractor will fatigue fail, (break), and then you are up the river without a paddle. You can look, but these extractors are out of production, and out of stock. When one of these breaks, your rifle is inoperative.

Before there was such things as detachable magazines, it was best policy to push rounds into the magazine. Now with these single stack, or double feed, single stack magazines, you have to remove the magazine in order to feed a round.

View attachment 1000145

View attachment 1000146

that three round magazine has sharp edges and cuts my fingers. I don't like it. However it is there so the manufacturer can use one receiver for a "family" of cartridges. Older cartridges had a lot of taper, but the modern crop are very straight sided. Taper is good for reliable feed and extraction. Taper is more tolerance of alignment issues with the magazine, cartridge, and action. That is one reason, I believe, the older military rounds were almost dart like in shape. For 1888's manufacturing technology, highly tapered rounds would feed, given the file to fit technology of the times. And, (and this is very important) taper allows smooth feeding. Abrupt shoulders will cause feeding issues as the things rebound off magazine and receiver surfaces. Moderns want as much powder in the case, so cases have become cylindrical, and abrupt shoulders are better for consistent ignition. Older cartridges would go bang, but the velocity spreads with their shallow shoulders were higher. Shooters today are looking for bench rest accuracy, and are willing to trade off function reliability, and live with single stack, finicky magazines, to get this.

Incidentally, the extractor;s primary function is to hold the round against the bolt face. If the round falls off the bolt face, you will have a jam. If the round is not held firmly against the side of the bolt face, it won't eject reliably. A round should fall out of the chamber after firing, if your rounds stick, you are creating future problems for your rifle. If you insist on loading your cartridges so hot that the cartridge sticks to the chamber, requiring the extractor to pull the case out of the chamber, that thin, extractor hook will break some day. I busted a M1903 extractor by putting a round in front of the extractor. It was designed to be fed from the magazine and to be loaded as a single shot.

here the magazine cutoff is turned to "off", so the rifle will not feed rounds from the magazine

View attachment 1000167

Considering many M1903 extractors are 80 to 100 years old, it might make sense to only feed from the magazine.

If you always feed a round from the magazine of a controlled round feed action, and don't load your rounds to the point they stick in the chamber, a controlled round feed extractor will last longer than a push feed extractor.

A push feed extractor will wear, luckily most of them are cheap and easy to replace, depending on the type. I have had one Garand extractor break, luckily the action jammed and not all the springs and parts were ejected. It can get expensive to replace all that stuff. Everyone who shoots an AR15 enough will wear out an extractor. I even bought the tool, I think I replaced one or two, been awhile. The push feed M70 has a bunch of different extractor blades, I met a guy who carried a small box of them. He was a match director, carried them to help competition shooters when their push feed M70's went down due to worn extractors. And, I helped a shooter one day replace his push feed extractor, on the firing line. It was easy. Wish I knew what extractor blades were required for which bolt faces and cartridges. The M70 extractor is easy to replace. The M700 is not.

View attachment 1000147

Something to know about the M700 extractor, keep the space under the extractor clean, or you will break it. And, super important, when you load cartridges so hot the case head expands, you will break the extractor, as it gets crushed between the case and bolt nose. So, don't load hot.

I do think the M700 is a fantastic design, it protects negligent re loaders, by sealing the breech in over pressure conditions.

View attachment 1000148

No one admits to doing stuff like this. If it were not for guys like Randall, you would never know this stuff happens.

View attachment 1000149

View attachment 1000150

View attachment 1000151

I prefer the controlled round feed for one particular reason: you can ease the bolt open, and not have the case eject itself forward of the firing line. This is so frustrating at CMP Talladega, all those shooter banging away, the concrete forward of the benches is sloped downwards, rounds ejected will inevitably roll in front of the red line. I am sure this is not the only range where brass kicked forward becomes a problem to retrieve.

Push feed design have become the dominate extractor due to cost considerations. It is easier and cheaper to make a rifle with a push feed extractor. Gun designs have been cheaper, less durable, because the customer is extremely price sensitive. (how many threads have you read that started with

best cheapest?) And, because the customer, is not shooting his weapon enough to wear anything out. Industry understands its customers and builds the things they will buy.

).

).