Wow, @Slamfire I didn't even know that over lubrication was an actual concern for some folks. At worst it seemed to be a minor inconvenience that excess lube ends up on your eye-pro.

I have written extensively about the Army coverup of their low number M1903's, a coverup that goes back prior to WW1. The Army built 1,000,000 rifles without temperature gages, so any time a part was heated, it was likely to be over heated. It is likely that the forge shop and heat treat ovens caused the most burnt receivers and bolts, but, lots of other parts probably got over heated too. Whenever a rifle blew up, the Army blamed greased bullets. Cupronickel bullets of the period fouled the barrel something awful. The Canadians had a practice of firing several 280 Ross cupronickel bullets and then firing steel jacketed bullets to remove the jacket fouling. Ross bullets were also greased, because putting grease on a bullet absolutely, positively, stopped the fouling. Many nations issued service rifle ammunition that was greased, the Austrians did it to because their armor piercing ammunition had steel jackets. the grease on the bullet spared the barrel. I know the Swiss greased their bullets, I think back to the days when they issued paper patched bullets. It must have done something else, like improved accuracy, or easy cleanup, because they greased their service rifle ammunition well after cupronickel jackets were replaced with better materials.

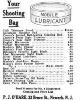

Target shooters who fired US issue cupronickel jacketed bullets had to grease their own ammunition or experience massive jacket fouling that changed the point of impact during a match. Cupronickel fouling was also a mess to remove, took nasty chemicals. This is an ad from the WW1 era, the mobile lubricant can was carried to the firing line and you dipped and twisted your bullet tips in the grease. I believe "never nickel" was a British bullet lubricant. These were all very common on the firing line.

An example of dip and twisting:

The Army being the open and honest institution it is, whenever a low number rifle blew up on the firing line, with issue ammunition, the Army blamed the shooter. The Army never acknowledged there was a problem with the ammunition or the rifles, nope the Army blamed the shooter for greasing their ammunition. Blamed the grease, saying that "grease pinched the bullet", and "increased bolt thrust", and because of the great authority of the Army Ordnance Bureau, shooters have accepted these reasons for over one hundred years. This is of course a coverup.

But, it is a century old coverup. It is so old that it has become part one of the core beliefs of the shooting society. A sort of "always been and always will be" faith. In a century, the theory has been built on, amplified, extended, stretched, evils never dreamed of by the original creators placed on grease and oil on cartridges. Maybe the election of a Democrat in Alabama is due to greased bullets, who knows the extent of evils caused! Over time, the inbred, ignorant, US Army, became lubrophobic (Lubrophobe - pathological fear of lubricants). This institutional fear created an irrational desire to keep weapons free of oils and greases.

You can see this in this WW2 manual:

TM 9-1904 Ammunition Inspection Guide 2 Mar 1944

http://archive.org/details/TM9-1904

The use of oil on cartridge cases is prohibited. Greasing or oiling cartridges used in machine guns and automatic arms cause the collection of dust and other abrasives which are injurious. Grease or oil on cartridge cases or on the walls of the chamber in nonautomatic rifles creates excessive and hazardous pressure on the rifle bolt. When there is oil on the cartridge case, there is no adhesion of the case to the chamber. When the case expands upon firing, the case slips back, and the bolt receives a greater rearward thrust. An apparent exception exists in the case of lead bullets. However, only the bullet is waxed or greased as issued.

Did you notice the non automatic warning? Few know the history of firearms, but the Oerlikon 20mm machine cannon used grease ammunition. No one seems to have picked up on the incoherent physics expressed by the Army. Grease or oil is OK in automatic weapons but not nonautomatic weapons. See, F=MA is different for bolt guns and automatic weapons. Right? I am certain those with a technical background will realize that F=MA is the same for non automatic weapons and automatic weapons, but the Army does not realize that, and those who believe everything the Army says, well, they will act as they are told.

Not everyone used an Oerlikon, no civilian I know ever owned a 20mm machine cannon, and so, even though the Oerlikon served through Vietnam, few were aware of the thing, and of course, people believe a lot of contradictory ideas, especially when taught by authority. (Many have been conditioned since birth to unconditionally accept everything that authority tells them) The Army, as an institution, still believes this, teaches its Soldiers, that oil and grease are bad, and that weapons are to be kept free of oil and grease. At least that is what my Vietnam veterans buddies were taught, and I believe this was also what the Army was teaching Soldiers as they deployed to Iraq and Afghanistan. Lubrophobia is not only nonsense, it will get you killed. It turns out the AR15/M16 is more reliable wet. Run it dry and it will stop functioning sooner. But, you won't do that if Authority tells you that oil and grease on the weapon create a dangerous condition. You will accept what they tell you, reject anything that contradicts what you have been taught, and you won't step over that line. The negative consequence is that you may die because of what you were taught.

The good guys in the video are trying to correct this nonsense, save lives, even though they don't know where it started.