Everyone looks at things differently. The gunblast articles are no different. All the looks/fit/groups/triger yada-yada-yada means nothing to me. I do however like seeing the pictures of their targets and recovered bullets. Those pictures will tell me more than any of the hype they are pushing. I'm not badmouthing any make of firearm. I do this will everything I find interesting & so should everyone else. Make no mistake about it, I absolutely take a hard look at everything I own/shoot.

A link to recovered bullets.

http://www.bing.com/images/search?q=recovered+bullets&FORM=HDRSC2

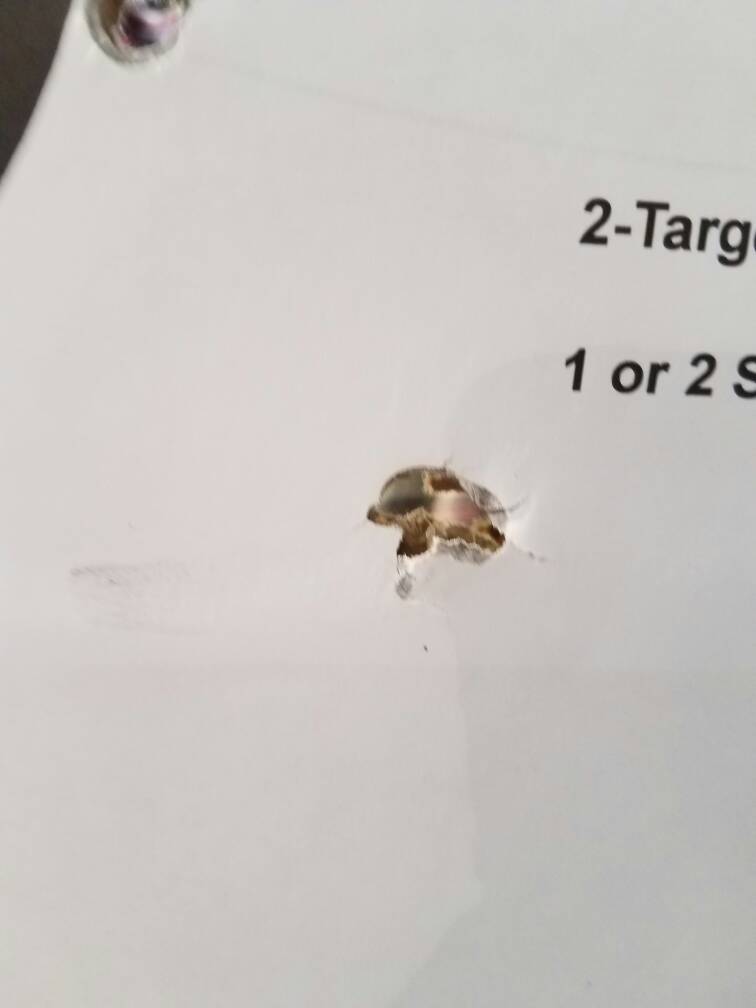

This is what the Realguns article showed for the recovered bullets shot from a ruger gp100/44spl.

On my computer is a free/simple/easy to use program called paint. I upload any picture that is of interest to me to a temp folder and then open the windows paint program and open the picture I uploaded and zoom in/magnify the the uploaded photo to get a better look at what's truly going on.

Same bullets but this time they are at 200% magnification. I see lead deposits on the jacketed bullets. I see burn marks on the jacketed bullets. I see rough land marks in the jacketed bullets.

This is telling me:

There was leading in the bbl

The bullet never sealed the bore

The bullet skidding caused the marks the lands left in the bullet.

Those bullets never sealed the cylinders and it took the bullets body up past the cannalure to seal the bbl. Hence the odd rifling marks bellow the cannalure.

realguns did a test with reloads in the 44spl gp100. They used 9.5gr of power pistol for this 200gr speer gdhp bullet. My Alliant 2012 reloading manual lists a 200gr "gshp" (gs ='s golden saber/sperr doesn't make gs/typo error) & 8.6gr of power pistol for the same load.

Realguns ='s 200gr gdhp/9.5gr power pistol

Alliant ='s 200gr gshp/8.6gr power pistol.

Realguns should be using a hot load. Their reload with the recovered bullets.

Same photo with 200% magnification in paint taking a hard look at the recovered bullets. While not the clearest it clearly shows the drive edge/side of the land failing and the blackened base of the bullet from escaping gases. Along with dark marks by the cannalure. Those dark marks are caused from the bullet being a larger diameter from the jacket being pushed outward from the swaging/imprinting of the cannalure the bullet. The material has to go somewhere and that larger bullet diameter just below the cannalure and above shows where the bullet actually sealed/expanded/grabbed the bbl for accuracy.

It pays to look at bullets fired from a fierarm, they will tell you what's really going on. I don't know the diameter of those different jacketed bullets but there was't enough pressure to get the to expand/seal the bbl.

A link to recovered bullets.

http://www.bing.com/images/search?q=recovered+bullets&FORM=HDRSC2

This is what the Realguns article showed for the recovered bullets shot from a ruger gp100/44spl.

On my computer is a free/simple/easy to use program called paint. I upload any picture that is of interest to me to a temp folder and then open the windows paint program and open the picture I uploaded and zoom in/magnify the the uploaded photo to get a better look at what's truly going on.

Same bullets but this time they are at 200% magnification. I see lead deposits on the jacketed bullets. I see burn marks on the jacketed bullets. I see rough land marks in the jacketed bullets.

This is telling me:

There was leading in the bbl

The bullet never sealed the bore

The bullet skidding caused the marks the lands left in the bullet.

Those bullets never sealed the cylinders and it took the bullets body up past the cannalure to seal the bbl. Hence the odd rifling marks bellow the cannalure.

realguns did a test with reloads in the 44spl gp100. They used 9.5gr of power pistol for this 200gr speer gdhp bullet. My Alliant 2012 reloading manual lists a 200gr "gshp" (gs ='s golden saber/sperr doesn't make gs/typo error) & 8.6gr of power pistol for the same load.

Realguns ='s 200gr gdhp/9.5gr power pistol

Alliant ='s 200gr gshp/8.6gr power pistol.

Realguns should be using a hot load. Their reload with the recovered bullets.

Same photo with 200% magnification in paint taking a hard look at the recovered bullets. While not the clearest it clearly shows the drive edge/side of the land failing and the blackened base of the bullet from escaping gases. Along with dark marks by the cannalure. Those dark marks are caused from the bullet being a larger diameter from the jacket being pushed outward from the swaging/imprinting of the cannalure the bullet. The material has to go somewhere and that larger bullet diameter just below the cannalure and above shows where the bullet actually sealed/expanded/grabbed the bbl for accuracy.

It pays to look at bullets fired from a fierarm, they will tell you what's really going on. I don't know the diameter of those different jacketed bullets but there was't enough pressure to get the to expand/seal the bbl.