I do know from reading an account of a WW2 Officer in Germany, that steel case 45 ACP was around, and may have been more common. The Officer carried a M1905 Colt, he got from his dad, I think, and he stated the M1905 would not run steel case 45ACP reliably. So he had to hunt to find brass case 45 ACP.

After the war, the US experimented with Teflon coated steel case ammunition, (I know of 30-06 and 20mm) because copper, tin, zinc, etc, are "strategic" materials. Even though the US had more copper than, lets say the Germans, it did not mean we could be wasteful. But after the war, I guess we got lazy, forgot the hoop jumping we had to do during the war, and stayed with brass case.

I found patents from the 1950's and 1970's on coating steel case ammunition with teflon

Patent US2972947A

Ammunition cartridge cases

https://patents.google.com/patent/US2972947?oq=polymer+coated+rifle++cartridge

We have found that the aforementioned difficulties in the operation of automatic rapid fire guns can be eliminated or in substantial measure reduced by modifying the exterior surface of the cartridge case to present to the wall of the gun chamber, a surface which is essentially sintered polytetrafiuoroethylene. This is accomplished in accordance with our invention by coating the exterior surface of the cartridge case with a thin film formed essentially of sintered polytetrafluoroethylene. An effective range of thickness for the sintered polymer coating is on the order of 0.2 to 0.6 mil. The thin coating may consist of a single layer or of several layers of the sintered polymer. Polytetrafiuoroethylene is a polymer known in the trade as Teflon.

Polytetrafluoroethylene

US 4041868 A 1977

http://www.google.com/patents/US4041868

A thin walled steel cartridge case having a substantially larger internal volume than a conventional cartridge case. The cartridge case is fabricated from a high strength, heat treated carbon steel or boron steel and the wall contour in the head area is designed to avoid localized high stress. A low friction coating is applied to the outer surface of the cartridge case and serves to reduce stress concentrations in the head area and to reduce extraction force in the event of interference between the case and the chamber during extraction

Russia was very pragmatic and designed from the very start, that the 7.62 X 39 case would be steel. That meant they studied manufacturing methods, steel thickness, steel alloys, expansion and contraction characteristics, and they came up with a round that functions with that material. The 45 ACP was always a steel case, and so its expansion and contraction characteristics may not be optimal with steel as a case material.

Wolf coats their ammunition with (I think) is sintered telfon, but they they stopped calling it a lubricant. This is what Wolf used to say:

Superior Reliability: The application of the polymer creates a precision uniform coating around the casing. It produces a bullet with persistent, uncompromising, stable dimensions thus leading to smooth reliable extractions.

Better Functioning: The superior lubricity improvement eases wear in gun chambers and alleviates excessive operational and maintenance issues associated with rapid firing. The development of this polymer represents a break-through in the field of tribology, and incorporates the most recent chemistry in terms of lubricity improving molecules.

This is what they say now:

Polyformance ammunition will not disappoint! Wolf coats all of their ammunition with a polymer coating to ensure smooth feeding and extraction putting the shooters mind at ease with less jamming. The coating on the ammunition allows for the ammunition to have a lengthier long term shortage time in comparison to different manufacturers

I am certain they have stopped alluding to Polyformance as a lubricant because the the extreme reaction they got from Hatcherites who understand greases and oils will "

increase bolt thrust"!!!! . There is an Army Ordnance Bureau coverup, over a century old, hiding the problems with their defectively built low number 03's. These low number 03's had receivers and bolts overheated at the factory, that is burnt, and these rifles were blowing up on the firing line. Shooters at the time were coating their bullets with grease, to reduce jacket fouling,

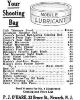

shooters took their bullets, and dipped them into the tin, and fired them, like this.

Since the blowups occurred with Army issue ammunition, and of course, the Army maintained that both their ammunition and rifles were perfect, the fault had to be with the grease! And this fraud is still a core belief today with many in the shooting community, and is still a basis for covering up Army Ordnance incompetence, even though there were plenty of machine guns with oilers, and trillions of oiled, greased, rounds were fired in combat. And even today, 22lr match ammunition is still greased, and the rifles and pistols using the stuff, function perfectly.

No big badda boom here:

Clark was a Bullseye National Champion, the guys at the shop know what they are doing.

I am going to say, if you are worried about steel case ammunition, put a drop of oil at the junction of each bullet and case, as you load it into your magazine. I have been doing this in Bullseye Pistol. That oil blows up the barrel, and reduces friction. I actually see a plume from the oil, at times. In match barrels I see little to no leading, and jacket fouling is non existent. (crappy barrels will lead and jacket foul no matter what you do) I will get back from a match, and my 1911 barrel only requires a patch to swab out the tube, if I oil every round. And, oil will come out the back of the chamber and lubricates the mechanism as I shoot. This is both good and bad. The mechanism is lubricated real time, fouling is solvated real time, and the bad is, I have to wipe off the gun, because there is oil leaking around the slide. The cases eject oily, which means, there is little to no case to chamber friction. And that has to be good if you are worried about steel case rubbing the chamber out.

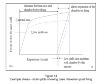

Oiling the teflon coating of Wolf cases will reduce case to chamber friction even more. The Navy ran a series of tests with their Oerlkon's, during the 1950's. They tried teflon 20m cases, chamber flutes, and of course, the greased cases they used through out WW2. The machine cannon ran fastest with oiled teflon cases. In the end, the Navy installed an oiler on the guns, and that configuration was used through Vietnam. This is the WW2 version that required pre greased ammunition.