Sorry, didn't understand what you were asking - I'll take another go.

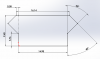

In the last drawing, the top plane is definitely positioned in relation to the bottom post. I imagine it would be important to do this to make it approximately centered so accessories fully seat on the rail. Being skewed too much one way or the other would either cause the corner of the rail to hit the mount or not provide enough area to fit securely. In short, the position of the lower 45 degree angles with respect to the top plane seems to be of particular importance, while the position of the bottom post only needs to be such as to prevent it from interfering with the previous two features.

Now, on the first drawing, I have no idea why the midpoint of the bottom 45 degree surface is positioned in reference to the top 45 surface, and vice versa. Unless there is an accessory that clamps solely on the angles, the upper surface seems geometrically unimportant. The dimensions based on these midpoints seem very strange to me. Again, it's hard to tell exactly what the intent was since the GD&T on Figure 1 just seems wrong in a few places.