Alemaniac

Member

- Joined

- Feb 20, 2019

- Messages

- 16

After firing 41 rounds of virgin 6.5x50 PPU brass that I personally loaded - 32gr of H4895 and 140gr Nosler partition, it was time to decap and resize the brass and prep for a second loading. Every case bulged after firing and I'm well aware of this - EVERYONE mentions the Type 38 has an oversized chamber and that the casings bulge after firing and I'm not here to discuss something that's been beaten to death.

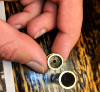

What really concerns me is this: after running each lubed case into my Lee full length decapping/resizing die, I noticed a large scratch ring where the bulge once was. Some cases the scratch ring is light while some the scratch ring is deep enough that I can run my fingernail into the groove.

Here's a photo of one of the really bad ones:

Is the integrity of the brass compromised?

I'm very hesitant about loading these again and worry about case-head separation or anything that could cause a major catastrophe while firing a second time.

Any thoughts on this?

What really concerns me is this: after running each lubed case into my Lee full length decapping/resizing die, I noticed a large scratch ring where the bulge once was. Some cases the scratch ring is light while some the scratch ring is deep enough that I can run my fingernail into the groove.

Here's a photo of one of the really bad ones:

Is the integrity of the brass compromised?

I'm very hesitant about loading these again and worry about case-head separation or anything that could cause a major catastrophe while firing a second time.

Any thoughts on this?