gbw

Member

Just curious.

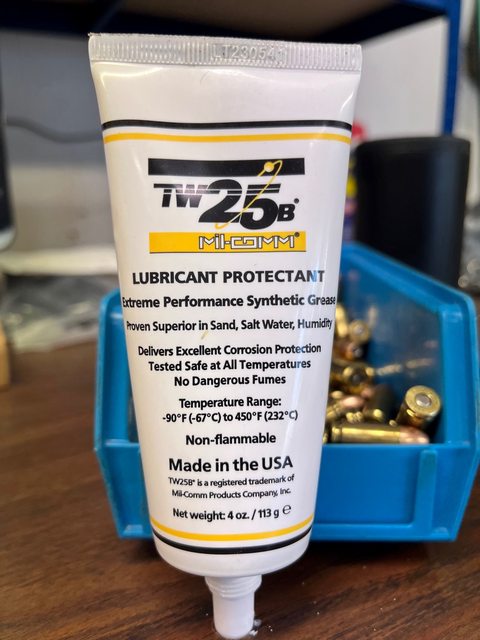

Everybody says we must grease sliding surfaces on Garands, M1Aa, &etc.

Not a huge fan of grease... On non-closed mechanisms it tends to get pushed away from where it's needed and must be frequently re-applied.

Also gets and holds dirt, sand, grit, and it's messy. Still, everyone seems to see the need.

On a Glock pistol I saw where the factory had applied a very small bead of anti-seize lube, looked like copper based, on the slide along high wear areas.

Glock factory folk know stuff.

So. Would this also be a good idea for the Garand and M1A lugs, op-rods, etc? These lubes are supposed to lay down a thin coat of anti seize material that stays put, at least that's what I've always heard.

Everybody says we must grease sliding surfaces on Garands, M1Aa, &etc.

Not a huge fan of grease... On non-closed mechanisms it tends to get pushed away from where it's needed and must be frequently re-applied.

Also gets and holds dirt, sand, grit, and it's messy. Still, everyone seems to see the need.

On a Glock pistol I saw where the factory had applied a very small bead of anti-seize lube, looked like copper based, on the slide along high wear areas.

Glock factory folk know stuff.

So. Would this also be a good idea for the Garand and M1A lugs, op-rods, etc? These lubes are supposed to lay down a thin coat of anti seize material that stays put, at least that's what I've always heard.