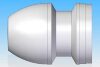

Proposing hollow base (HB) conical bullet for 36 cal revolver. It has a rebated dia bottom for easier reloading.

Blue ring is just proposal for an O-ring that could be inserted to create a better seal and prevent a chain fire from the front of cylinder.

Bullet weight in hollow base configuration will be 140 grains, with solid base will be about 163 grains.

There is manufacturer of Cramer style molds that could make a mold with additional pins, so you just replace them, and you can cast solid base bullets. However, before making any further step, I would like to see first what would be your response.

Please let me know what do you think about this design, thanks.

Blue ring is just proposal for an O-ring that could be inserted to create a better seal and prevent a chain fire from the front of cylinder.

Bullet weight in hollow base configuration will be 140 grains, with solid base will be about 163 grains.

There is manufacturer of Cramer style molds that could make a mold with additional pins, so you just replace them, and you can cast solid base bullets. However, before making any further step, I would like to see first what would be your response.

Please let me know what do you think about this design, thanks.

Last edited: