TheOutlawKid

Member

- Joined

- May 31, 2018

- Messages

- 1,480

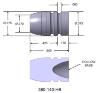

I have a design that is like a tapered REAL bullet..but for .36 cal and with a wider meplat. Its only 130 grains but its a hard hitter. One thing i would have changed is smaller lube grooves. My design has huge grooves...wide and deep. Such large lube grooves arent needed for such a short barrel. I saw no difference when using the same exact lube but in a bullet with a smaller lube groove. Now if used in a rifle with a long barrel then that is a different story, not so for a revolver with a barrel that's 8 inches or shorter. Some folks swear by big lube bullets and theyre great...but the large deep lube grooves in my testing werent necessary compared to a bullet with lube grooves such as the one mr.rodwha posted/designed...but again this is in revolvers...rifles is a whole different case and the more lube the better. Also the lube type makes a huge difference, some lube types require more and others less to achieve the results wanted. Heres my REAL type design next to a Kaido conical.

Again...if i could remake the mold id choose shallower lube grooves to add more weight to the bullet.

Again...if i could remake the mold id choose shallower lube grooves to add more weight to the bullet.