I bought an ACP, reluctantly, and it turned out to be an even worse piece of garbage than I feared. The absolute worst of what makes Lee awful. I tried to make a warranty claim for the numerous problems and found they discontinued it and would not support it. What they would offer me is a discount on the APP Deluxe. Although I found this extremely offensive, ultimately, I wanted something that works. I had already said that I would have paid twice as much if it would just work. I just want it to work. Please. I've got work to do. So I bought the APP. I didn't convert the ACP, but bought the APP Deluxe outright.

I use the APP Deluxe for priming, particularly higher volumes of cases. The other night I primed 700 revolver cases. With my hand primer, I limit myself to 150 per session to save the tendons in my elbow. With the APP, I think I could do at least a few thousand before I just got bored. It doesn't work perfectly. I get a primer turned sideways sometimes, and it's impossible to see since its hidden by the feeding mechanism and then the case itself. It's not a foolproof operation either. If I stroke it after the column of brass in the feeder is empty, it will still feed a primer and then when I start feeding cases again, another stroke will double-feed a primer. Clearing the machine from my faults is a little tricky, but it can be learned and a brass pick helps. It can be avoided altogether if I don't make any mistakes. The only thing I fault the machine for is the occasional sideways mangled primer and an occasional mashed case mouth where the fingers mash it despite proper alignment. It's less than 1 in 100. I can use my RCBS hand primer as fast as the APP, but it will have faults at a similar rate when I'm moving that fast, and I already explained I cannot use the hand primer for anywhere near the volume the APP produces easily. So I would absolutely use the APP if I was going to prime hundreds or thousands of cases. 20 to 50 cases, and I would use the hand primer.

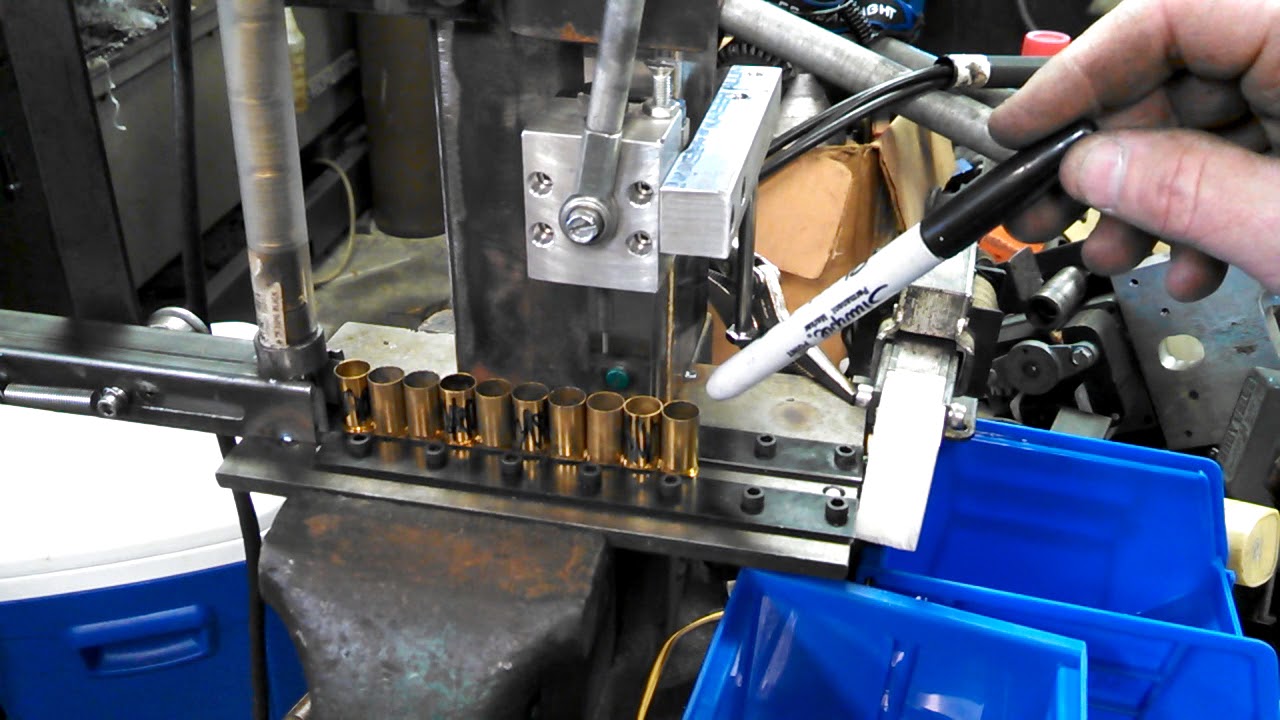

For resizing handgun brass I use a Lee Pro 4000 -- actually an ABLP with the case feeder etc. I've had that for about 5 years now and it has processed tens of thousands of cases. I won't use it for rifle brass anymore, even though it does process 223/556 and 6.5 Grendel, both of which I reload for, and I have reloaded thousands of Grendel on it, I have a better single stage press for that now. I've always used the Lee Pro 4000 for depriming, even rifle brass (it will deprime longer rifle brass than it can load). Until I got the APP, it was the only deprimer I had with a case feeder. I haven't deprimed on the APP yet. I'll wait until I have a few thousand to deprime. I have used the Pro 4000 for charging, seating, and crimping many thousands of cases. I found the on-press priming another one of Lee's hopeless pieces of junk, so I was never successful in loading anything all the way through. That's why I doubt I would ever use a six-station press. If the Pro 6000 has a better priming system, that could be a reason to get it. But I will not go back to powder charging or seating on a progressive, so the six die stations are still superfluous to me.

Bottom line: I can suggest considering the APP Deluxe for priming in the volume of hundreds to a few thousand cases at a time. For this volume level, a Lee progressive press and case feeder has been a good solution for depriming and case sizing handgun brass -- even if those are done separately. The case feeder makes it worthwhile even for a single operation like a universal depriming die.