CapnMac

Member

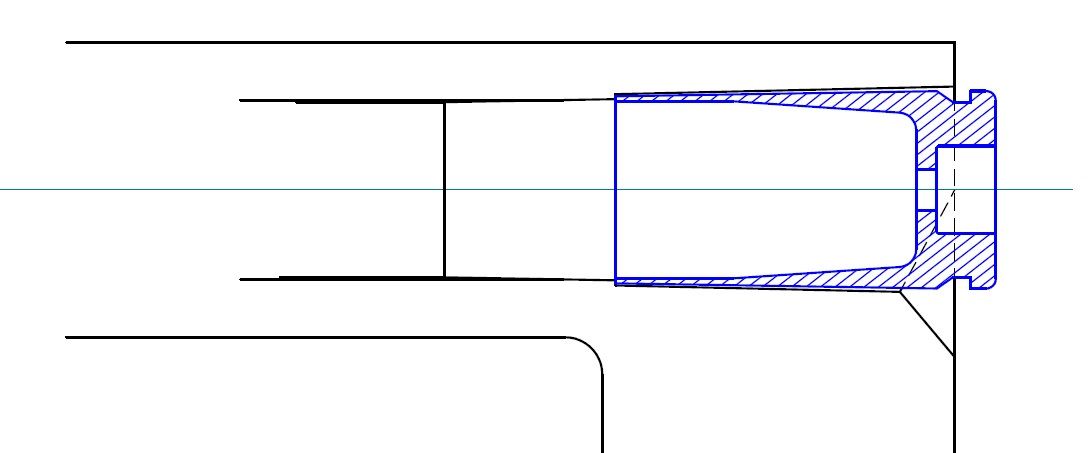

In self-loading pistols, usually the debating dilemma begins with how the barrel is "ramped" (if at all).

What seems to occur is that more credence is given to barrels where the ramp protrudes from the rear face of the barrel. And the least credence given to those where the barrel is slightly undercut at the chamber so as to not need a pokey-out sort of ramp at all.

Such thigs are often debated, and hotly, with little or no actual experience by owners using factory-spec ammo. (And, often, with many citations of circumstantial, second or third hand accounts of badly-assembled ammo.)

So, this winds up a "hot topic" online, sounds and furies, oft told by idiots, signifying nothing.

What seems to occur is that more credence is given to barrels where the ramp protrudes from the rear face of the barrel. And the least credence given to those where the barrel is slightly undercut at the chamber so as to not need a pokey-out sort of ramp at all.

Such thigs are often debated, and hotly, with little or no actual experience by owners using factory-spec ammo. (And, often, with many citations of circumstantial, second or third hand accounts of badly-assembled ammo.)

So, this winds up a "hot topic" online, sounds and furies, oft told by idiots, signifying nothing.