Lefty38-55

Member

FYI, I make Range Rods from thick wall tubular brass, as it has 95+% of the strength, but only ~1/2 the weight vs. a solid rod. I will add that brass prices sure have gone UP ... so check around for pricing, as the parts appear more expensive than from the last time I made some, no thanks to Bideconomics! I had bought enough to make 3 and they were only about $22 each back then (only a year or so ago), plus add a few bucks or two for whatever your handle of choice is, e.g., a 2" wooden ball is $1 or so at local hobby store, or other brass or material needed if you want to make an accessory T-Handle.

From the picture to follow, top to bottom, the parts are:

Assembly:

-Cut the ENDS from the 4" extension into two 2" long pieces and remove the male 10-32 stud from one end of each

-Cut the MAIN ROD to your desired length

-Cut two 3" long sleeves from the larger SLEEVE tubing, your 'sleeve' could be longer if you think YOU need more strength there ...

-Insert the solid END, so that the 10-32 threaded hole shows flush, into the 3" SLEEVE - Glue and pin together. I use a LokTite product that makes up space between pieces and permanently bonds them together (epoxy would work too!). Then pin with a brass pin/brad peened into a countersunk hole on each end.

-Then insert the MAIN ROD into the 2" of the SLEEVE on the solid END you just put together - Glue and pin together.

-Do the same for the handle end, making sure the tapped 10-32 female hole is flush at the end. When using 2" or so wooden balls for a handle, I tap drill a 1-1/2" machine bolt 10-32 that's epoxied into the ball, leaving 1/2" out. I also made up some T-Handles too ... but so far have never needed them.

There you go ... a CUSTOM length - light but strong - brass tubular Range Rod for only $25 or so (maybe more now with Biden Priceconomics)!

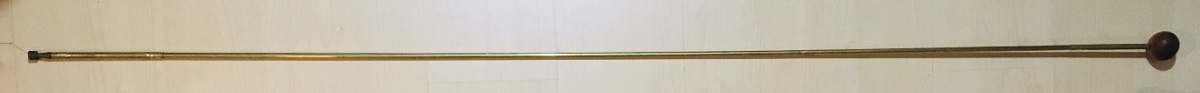

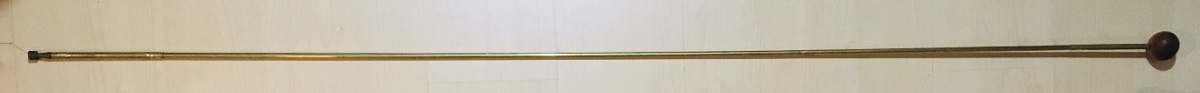

A 64" ramrod for my 60" barreled firelocks. The two 2" ends added 4" overall to the length. The rod almost appears 'bent' in the photo, but that is due to the lighting only.

Accessory Tip End - Some may not care for the 'spliced section' ... but for loooooong rods like I use, believe me, the tubular brass is perfect! As is, I need to tip those long firelocks over at a good 45 to 60 degree angle to load them ... that would be much more difficult with a HEAVY and long range rod!

Handle End

From the picture to follow, top to bottom, the parts are:

- 11/32" OB brass tubing, bought in a 36" length - This is the SLEEVE

- 5/16" OB thick wall brass tubing, bought in a 6' length (I would only use thick wall tubing here) - This is the MAIN ROD

- 5/16" ramrod extension, 5/16" OD solid brass, threaded 10-32 on both ends, $5 from Muzzleloaders Builder Supply - These will be the ramrod threaded ENDS

Assembly:

-Cut the ENDS from the 4" extension into two 2" long pieces and remove the male 10-32 stud from one end of each

-Cut the MAIN ROD to your desired length

-Cut two 3" long sleeves from the larger SLEEVE tubing, your 'sleeve' could be longer if you think YOU need more strength there ...

-Insert the solid END, so that the 10-32 threaded hole shows flush, into the 3" SLEEVE - Glue and pin together. I use a LokTite product that makes up space between pieces and permanently bonds them together (epoxy would work too!). Then pin with a brass pin/brad peened into a countersunk hole on each end.

-Then insert the MAIN ROD into the 2" of the SLEEVE on the solid END you just put together - Glue and pin together.

-Do the same for the handle end, making sure the tapped 10-32 female hole is flush at the end. When using 2" or so wooden balls for a handle, I tap drill a 1-1/2" machine bolt 10-32 that's epoxied into the ball, leaving 1/2" out. I also made up some T-Handles too ... but so far have never needed them.

There you go ... a CUSTOM length - light but strong - brass tubular Range Rod for only $25 or so (maybe more now with Biden Priceconomics)!

A 64" ramrod for my 60" barreled firelocks. The two 2" ends added 4" overall to the length. The rod almost appears 'bent' in the photo, but that is due to the lighting only.

Accessory Tip End - Some may not care for the 'spliced section' ... but for loooooong rods like I use, believe me, the tubular brass is perfect! As is, I need to tip those long firelocks over at a good 45 to 60 degree angle to load them ... that would be much more difficult with a HEAVY and long range rod!

Handle End

Last edited: