I did this with my 300 BO, I bought honing stones from Brownells and cutting oil. Attached it to a drill with 800 grit soaked in oil. Brownell's sells a number of grits levels. I would go slow, so not to take to much metal off at a time.How would I go about doing that? I think it would work.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

lee undersized sizing die 9mm

- Thread starter Hockey7711

- Start date

- Status

-

Not open for further replies.

Hockey7711

Member

- Joined

- Nov 15, 2020

- Messages

- 249

Interesting

Jim Watson

Member

It's not just my loads, it has also done it with factory ammo.

Could it be the chamber has very lo tolerances

The gun is defective, get the chamber reamed or complain to the importer.

I have not heard of anybody working on these, best to contact the importer.

There are no "lo tolerances". All chamber tolerances are plus. It can be larger than the blueprint but not smaller. If it is smaller, it is defective.

Hockey7711

Member

- Joined

- Nov 15, 2020

- Messages

- 249

I've heard some Glocks have tight chambers.

Jim Watson

Member

Gen 5 Glocks have smaller chambers than previous variants, trading reliability for accuracy.

rfwobbly

Member

That's like saying, "My 2 beagles don't bite people, therefore my Pitbull is not a danger to anyone."I'm usually using loads with a col of 1.09, so I don't think that is the problem.

They work on my other three 9mm's with no problem.

I don't know how to figure out the exact chamber size for this gun.

Guns can be a different as dogs. Each manufacturer cuts their chamber differently, even though most chambers comply with SAAMI specs. This is especially true of Eastern European guns because (by law) they don't have access to JHP or other fancy bullet shapes common in the USA. Here's a cartoon to try and show what I mean...

Now all 3 of those are 9mm, but none of them are alike. And when it comes to chambering ammo, each will have its "likes" and "dislikes". And that's what I'm trying to tell you. Each different brand, weight, and style of bullet interfaces with each brand and model of barrel in a completely totally different and uniquely individual way, due to the manufacture of the gun.

If you want to reload ammo for the 9mm, then each bullet has to be considered, measured, and then seated to a totally unique OAL.

• And that OAL may not be in your load manual.

• And not all bullets can be loaded into all barrels. Some barrels simply won't accept specific bullets.

Hope this helps.

Last edited:

rfwobbly

Member

My friend, you are casually tossing around general statements with absolutely ZERO specifics.This is a GSG MP-40

It's not just my loads, it has also done it with factory ammo.

Could it be the chamber has very lo tolerances that even as you fire 50 rounds or so, it gets dirty enough not to chamber a new round?

• Exactly what year and model gun ? If you are talking about a Glock, then you also need to quote the "Generation".

• Exactly what factory ammo ?

We can't help you until you start quoting EXACT specifics.

jmorris

Member

- Joined

- Sep 30, 2005

- Messages

- 24,241

It's not just my loads, it has also done it with factory ammo.

If I had a 9mm that didn’t run on factory ammo, I would have it fixed before I went to the trouble of making special ammunition for it.

Hockey7711

Member

- Joined

- Nov 15, 2020

- Messages

- 249

As I said it's a gsg mp-40.

The CCI Blazer 115gr worked well the other day, I just reloaded that brass with a HiTek 115gr,

using 3.1 gr of Clays with a COL of 1.10

I'll see how they work tomorrow.

The brass that seems to have problems are the S&B and another marked CBC. I'm not sure what that is. I'm filtering those out of my supply.

btw, I also had problems with the S&B in my Taurus GX-4.

The CCI Blazer 115gr worked well the other day, I just reloaded that brass with a HiTek 115gr,

using 3.1 gr of Clays with a COL of 1.10

I'll see how they work tomorrow.

The brass that seems to have problems are the S&B and another marked CBC. I'm not sure what that is. I'm filtering those out of my supply.

btw, I also had problems with the S&B in my Taurus GX-4.

A headstamp of CBC indicates Companhia Brasileira de Cartuchos out of Brazil.another marked CBC. I'm not sure what that is.

Their American company is Magtech which also handles MEN (Germany) and S&B (Czech Republic)

Hockey7711

Member

- Joined

- Nov 15, 2020

- Messages

- 249

Interesting, thank you.

The Glockodile

Member

- Joined

- May 6, 2020

- Messages

- 1,688

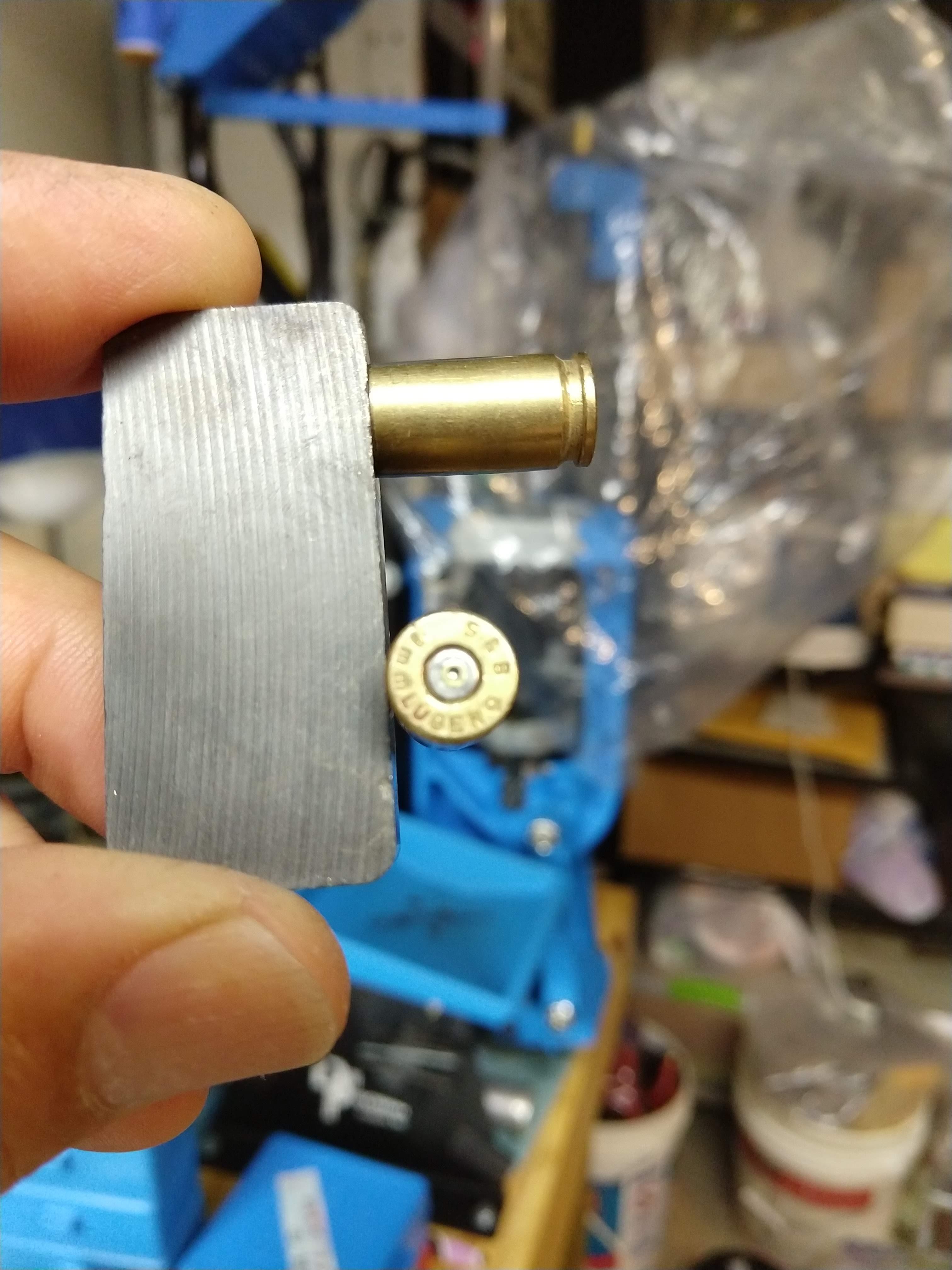

► Due to the construction of the standard Lee 9mm Sizing Die, I believe all cases come out under-sized. Lee makes a good die, but they also prevail in keeping their costs low. The 9mm case represents a unique design problem. Unlike 45ACP, 40 S&W, 38Spcl, 357Mag or other common straight-walled cases, the 9x19 Luger case has a taper. If Lee were to use a tapered carbide their cost would go up considerably. So I believe they use a non-tapered carbide ring, which works terrifically well, but leaves the 9mm case slightly undersized. SAAMI defines maximum case dimensions, and so being undersized is simply not an issue.

How would you say the Dillon Carbide Dies figure?

Jim Watson

Member

Once upon a time, a carbide sizing die for 9mm cost more than, say .38 Special, because it had a longer tapered carbide insert for the tapered case. .30 Carbine was as much or more.

Prices are the same, now, so either they have quit making the tapered inserts or have gotten their manufacture down to where they can charge the same.

Prices are the same, now, so either they have quit making the tapered inserts or have gotten their manufacture down to where they can charge the same.

rfwobbly

Member

• OK, you have a German-made 9mm gun. Germans are not allowed to have any bullets other than jacketed RN, what we call FMJ, like the Blazer 115gr.As I said it's a gsg mp-40.

The CCI Blazer 115gr worked well the other day, I just reloaded that brass with a HiTek 115gr, with a COL of 1.10.

• You are assuming that the ogive of the Blaser FMJ matches the ogive of the lead RN HiTek 115gr. That is a HUGE assumption. Cast RN often have a more blunt ogive than FMJ.

• Here we go again with the 2 place decimals. Did you measure the chamber with this NEW bullet to arrive at your OAL of 1.10", or did you simply guess ?

• Did you by any chance place a magnet on your S&B brass ? They may not be brass.The brass that seems to have problems are the S&B and another marked CBC. I'm not sure what that is. I'm filtering those out of my supply. btw, I also had problems with the S&B in my Taurus GX-4.

Last edited:

rfwobbly

Member

I don't see nearly the "Coke bottle effect" when using Dillon dies, as I do when using Lee dies.How would you say the Dillon Carbide Dies figure?

Hockey7711

Member

- Joined

- Nov 15, 2020

- Messages

- 249

I use the data from the hodgdon website for the bullet and powder I'm using. They give you the col data too.

I fired the reloaded cci blazer shells and they worked fine. No jams or light primer strikes. I also fired 50 factory magtech 115 gr fmj. They worked fine too but after about 80 rounds the feed ramp is noticably dirty,as I am sure the chamber is dirty too. So then I had a couple of light primer strikes in a row with the factory ammo.

My thinking is that the chamber may be slightly undersized and when it starts to get a bit dirty, the problems start.

I'll try the magnet with the s&b, it does look like brass, but maybe you're right.

I fired the reloaded cci blazer shells and they worked fine. No jams or light primer strikes. I also fired 50 factory magtech 115 gr fmj. They worked fine too but after about 80 rounds the feed ramp is noticably dirty,as I am sure the chamber is dirty too. So then I had a couple of light primer strikes in a row with the factory ammo.

My thinking is that the chamber may be slightly undersized and when it starts to get a bit dirty, the problems start.

I'll try the magnet with the s&b, it does look like brass, but maybe you're right.

rfwobbly

Member

No, sir. Very sorry, but you are grossly misinterpreting what they are telling you.I use the data from the Hodgdon website for the bullet and powder I'm using. They give you the col data too.

They are NOT giving you the OAL. They are NOT suggesting an OAL. They are NOT recommending an OAL.

Read the manual. No where in the manual does it say we want you to use this OAL.

The load data is a REPORT. They are reporting the amount of powder and cartridge length because that combination produces a specific chamber pressure. The load manual is reporting chamber pressure because that's what kills people. OAL doesn't kill. Powder weight doesn't kill. Everything we do in reloading is to control chamber pressure, which can and will kill you.

All the manual is saying is: "We shot this amount of powder with a bullet at this OAL and no one died. Now, go make it work for you."

Reasonable people would know that if the OAL is reduced, then to get the same chamber pressure, one should also reduce the amount of powder. So, all the reloading data is giving you is a safe starting point. The reloader is free to vary things as needed for their gun.

Why would you reduce the OAL? Because of the way that specific bullet fits that specific barrel. If you are assuming that all bullets are externally shaped alike, then you'd be wrong. That's very easy to see for yourself. Similarly, all barrel chambers are also internally shaped differently. You will prove that to yourself when you measure several chambers.

When you finally take the 15 minutes to prove to yourself that all bullets and all barrels are different, then you might have a Eureka Moment and realize that some of the assumptions you are using are false, and therefore some of those assumptions are unsafe. You may discover that there is more to reloading than simply reading a number from a website and blindly using that number.

What I'm trying to prove to you is that your assumptions are unsafe. At some point your procedure will get you hurt. Please don't do that.

LiveLife

Member

There have been a lot of good information provided by members but I can see how OP may not be utilizing that information to resolve the problem of finished rounds not fully chambering when factory rounds do.One of my guns has a tight chamber ... GSG MP-40 ... CCI Blazer 115 gr worked well ... reloaded ... lee carbide 4 die set ... HiTek 115 gr ... 3.1 gr Clays with COL of 1.10 (1.09")

Short Answer - I have experienced similar problem (Especially with larger sized coated bullets) as I reload for several aftermarket/match barrels with different chamber wall diameter and leade/freebore length before the start of rifling. The cause of the problem turned out to be:

- Diameter of the bullet/out-of-round bullet - Coated bullets are sized larger around .356"+ but can become oval in shape to .357"+ (Maybe from shipping damage/being dropped or from manufacturing?) when measured several times around the bullet.

- Thickness/inconsistency of case wall - Depending on the headstamp, I found case wall thickness can be inconsistent in thickness at case mouth and more importantly, further down the case neck where base of bullet gets seated. Since the taper crimp die only works around the case mouth, bulging of case neck further down during seating where taper die can't reach could cause the finished round to rub the chamber wall. And case wall thickness could be not even around the case and when inconsistent case wall thickness is stacked on top of out-of-round bullet, finished round could get even more oval to rub with chamber wall.

- Tilting of bullet during seating - Even with round bullet and consistent thickness case wall brass, bullet tilting during seating can cause the case neck of finished rounds to be out-of-round expressed by bulging of case neck on one side instead of being even around the bullet base.

I have done this - https://www.thehighroad.org/index.p...l-for-9mm-glock-19.653464/page-2#post-8093783For a more permanent fix, you could hone your chamber to open it up a little.

But I suggest OP try different solution options that worked for me before considering modifying factory barrel and likely voiding the warranty.

Long Answer - SAAMI specs have minimum to maximum and while factory barrels have typically been made more generous to SAAMI max dimensions, in recent years more and more manufacturers have started to make barrels closer to SAAMI minimum dimensions. So while factory ammunition manufactured to SAAMI minimum dimensions continue to work with these "tighter" barrels, our reloads that worked in more generous SAAMI max barrels may not work in these "tighter" barrels.

Another thing that has occurred over the years is shortening of leade/freebore length (Space bullet jumps from case neck to start of rifling). So bullets, even FMJ/RN that worked fine loaded to SAAMI max now must be loaded shorter to clear the start of rifling of newer factory barrels with shorter leade. FYI, this thread illustrates differences in various factory/aftermarket barrel leades and OAL of different bullets that must be used to clear the start of rifling - https://www.thehighroad.org/index.p...let-max-working-oal-col-for-reference.848462/

And if you are using 1.100" OAL simply because that's what Hodgdon load data lists for 115 gr Lead RN, you should conduct the "plunk test" to determine the max/working OAL. Here's a post that covers determining max/working OAL along with step-by-steps of load development -

https://www.thehighroad.org/index.p...124-gn-bullet-load-data.875597/#post-11652985

That could be as blowback action carbines can experience faster fouling buildup as gas leak around the case mouth/neck when bolt/buffer move away from the chamber. Us reloaders and 3Gun match shooters addressed this issue by increasing the combined bolt/buffer weight to extend the dwell time the bolt/buffer stay in contact with the chamber for more complete powder combustion (less soot on case) along with using different powders/charges (I found faster burning powders to improve soot on case issue and accuracy potential).It's not just my loads, it has also done it with factory ammo ... Could it be the chamber has very lo tolerances that even as you fire 50 rounds or so, it gets dirty enough not to chamber a new round?

I see that you are using faster burning Clays but at start charge of 3.1 gr. With blowback action carbines, I found I get improved powder burn and greater accuracy at near max/max load data. As to reliable feeding/chambering (That may be what you are experiencing also as expressed by GSG MP40 review below), you may need to use higher powder charge to push the bolt/buffer/spring back further to cycle/strip rounds from the magazine and fully chamber.

Here's a TAG review of GSG MP40 that expressed problems of failure to feed/chamber and soft primer strikes with factory ammunition. Your problem may turn out to be gun related, not reloading related but we will talk about reloading related issues on this post - https://www.thetruthaboutguns.com/gsg-mp40-gun-review/

In this myth busting thread, CBC and S&B brass were found to have thicker case wall at case mouth and case neck -The brass that seems to have problems are the S&B and another marked CBC. I'm not sure what that is. I'm filtering those out of my supply. btw, I also had problems with the S&B in my Taurus GX-4.

https://www.thehighroad.org/index.p...nd-bullet-setback.830072/page-4#post-10926900

Instead of more typical 0.011" average thickness at 0.100" below case mouth where taper crimp is applied, CBC and S&B cases were 0.01256" and 0.0126". More importantly, 0.200" below case mouth where typical 115 gr FMJ/RN bullet bases are seated to, CBC cases had the thickest wall at 0.0144" where typical thickness was 0.012"-0.013".

So with thicker .356" sized coated bullets seated to 1.100" OAL, you are going to bulge the thicker case neck more to rub with chamber wall which would prevent full chambering of the finished rounds. If your coated RN bullet profile (ogive) allows longer OAL, you can try to see if longer OAL rounds will work with the barrel. If not, you will need to cull the brass with thicker walls, use different profile bullet or smaller .355" sized bullets. (See comparison picture of different profile bullets)

BTW, here's a listing of average case wall thickness 0.200" below case mouth from the above link:

.0144" - CBC

.0138" - PPU

.0137" - GECO

.0135" - HRTRS

.0135" - Tulammo

.0133" - S+B

.0132" - WIN

.0131" - GFL

.0130" - AGUILA

.0130" - PERFECTA

.01225" Starline

.0122" - PMC

.0121" - R-P

.0115" - .FC.

.0111" - SPEER

.0110" - BLAZER

.0138" - PPU

.0137" - GECO

.0135" - HRTRS

.0135" - Tulammo

.0133" - S+B

.0132" - WIN

.0131" - GFL

.0130" - AGUILA

.0130" - PERFECTA

.01225" Starline

.0122" - PMC

.0121" - R-P

.0115" - .FC.

.0111" - SPEER

.0110" - BLAZER

Since case wall thickness is around 0.011" at case mouth, I usually add 0.022" to the diameter of the bullet for taper crimp amount (Which will essentially return the flare back flat on the bullet and skosh more). So for .356" sized bullet, I use .378" taper crimp.Just checked a factory round, it was..36 at the mouth and..37 after

To ensure accuracy of your calipers and that you are using the calipers properly, I suggest use of .355" pin gage and practice with eyes closed - https://www.thehighroad.org/index.p...ks-for-digital-calibers.821135/#post-10545265

I also use Lee carbide die set where third die is combination seat/taper crimp die and fourth die is Factory Crimp Die.lee carbide 4 die set

I do not need to use the FCD as various .355"/.356" sized bullets (lead, coated lead, plated, jacketed) work well even in the "tightest" barrel I have with shortest leade. Below is picture of .356" sized MBC 124 gr Hi-Tek coated RN with longer bullet base seated deeper at 1.050" and finished rounds will fully chamber in my Lone Wolf barrel with shortest leade -

https://www.thehighroad.org/index.php?threads/missouri-9mm-rn-help.870451/#post-11545654

If your finished rounds are out-of-spec/out-of-round as outlined in the "short answer", you could use the FCD to "fix" the case neck by post-sizing the finished round back to SAAMI specs but I prefer to load without the FCD.

I believe this applied to 40S&W Glock barrels where over the generations, chamber mouth and case base support improved.I've heard some Glocks have tight chambers.

For 9mm Glocks barrels, I believe chamber size/rifling/leade length remained the same with the exception of Gen5 Glock Marksman Barrel which utilizes different rifling type and shorter leade - https://www.thehighroad.org/index.php?threads/beginner-reloading-problems.877215/#post-11688158

Last edited:

packetloss

Member

- Joined

- Apr 28, 2020

- Messages

- 450

As I said it's a gsg mp-40.

The CCI Blazer 115gr worked well the other day, I just reloaded that brass with a HiTek 115gr,

using 3.1 gr of Clays with a COL of 1.10

I'll see how they work tomorrow.

The brass that seems to have problems are the S&B and another marked CBC. I'm not sure what that is. I'm filtering those out of my supply.

btw, I also had problems with the S&B in my Taurus GX-4.

CBC = Complete BS Case. I just toss them as the brass is very thick and they don't case gauge after being reloaded. S&B is thick as well, but not as thick as CBC.

Last edited:

LiveLife

Member

First time I ran into thicker walled CBC case that didn't pass the barrel "plunk" test I went, "What the heck? ..." and after some head scratching and adjusting the taper crimp die, I realized the case neck below where the taper crimp is applied was where it was rubbing the chamber wall.CBC = Complete BS Case. I just toss them as the brass is very thick and they don't case gauge after being reloaded. S&B is thick as well, but not as thick as CBC.

I could have pulled out the FCD to post-size the finished rounds but decided to sort out thicker walled cases (Hence the myth busting thread to check case wall thickness of various headstamp cases).

So now I set aside thicker walled cases to be used with pulled bullets and .354" sized bullets (Yeah, .354" 9mm bullets exist) along with tighter primer pocket once-fired cases to be swaged (S&B/RWS) when I go through crimped 5.56 and 9mm cases.

When life gives you lemons, you make lemonade.

Same as using slightly larger diameter metric primers in well used brass with enlarged primer pockets to extend the life of brass usage.

Hockey7711

Member

- Joined

- Nov 15, 2020

- Messages

- 249

Alot of info thanks to all. It will take some time to digest.

Thanks

Thanks

Jim Watson

Member

The bullet shown as Dardas Roundnose (I use Bayou and Brazos coated bullets from that mold.) has a shoulder that seats like a SWC. It gives longer OAL in short throated chambers.

Zendude

Member

First time I ran into thicker walled CBC case that didn't pass the barrel "plunk" test I went, "What the heck? ..." and after some head scratching and adjusting the taper crimp die, I realized the case neck below where the taper crimp is applied was where it was rubbing the chamber wall.

I could have pulled out the FCD to post-size the finished rounds but decided to sort out thicker walled cases (Hence the myth busting thread to check case wall thickness of various headstamp cases).

So now I set aside thicker walled cases to be used with pulled bullets and .354" sized bullets (Yeah, .354" 9mm bullets exist) along with tighter primer pocket once-fired cases to be swaged (S&B/RWS) when I go through crimped 5.56 and 9mm cases.

When life gives you lemons, you make lemonade.

Same as using slightly larger diameter metric primers in well used brass with enlarged primer pockets to extend the life of brass usage.

I had an issue with neck tension on a 3 of my 9mm reloads this past weekend. Two were S&B and the other was CBC. The bullets didn’t set back but rather pulled out of the case.

I use Lee dies, and one bothersome comment in this thread is whether the Lee sizing die sizes the full length of the case. I don’t understand how it would work at all if it did not size the entire case, only sizing the base of the brass near the rim instead. It doesn’t seem that a crimp die would be appropriate for resizing the case mouth and proper neck tension would never really be achieved.

greyling22

Member

No, sir. Very sorry, but you are grossly misinterpreting what they are telling you.

They are NOT giving you the OAL. They are NOT suggesting an OAL. They are NOT recommending an OAL.

Read the manual. No where in the manual does it say we want you to use this OAL.

The load data is a REPORT. They are reporting the amount of powder and cartridge length because that combination produces a specific chamber pressure. The load manual is reporting chamber pressure because that's what kills people. OAL doesn't kill. Powder weight doesn't kill. Everything we do in reloading is to control chamber pressure, which can and will kill you.

hey wobby, FWIW, I'm using the black responsive (green) style for thehighroad, and that blue font you are using is very hard to read. shows up on the earth tones style very well.

- Status

-

Not open for further replies.