I am thinking about picking up an annealing machine.

What's your go to annealed?

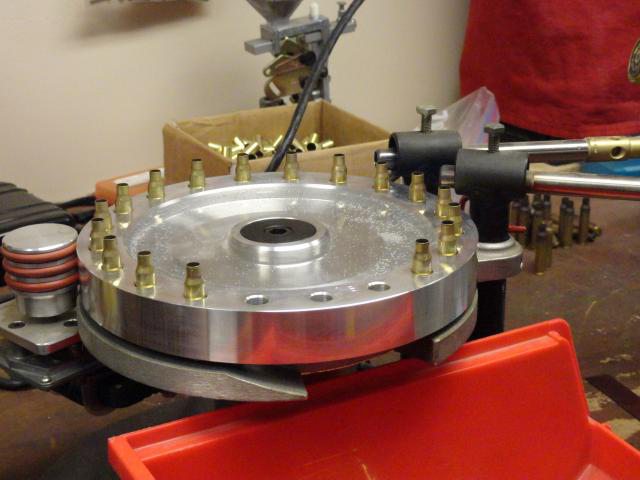

Dillon Case Feeder + AMP Mate + AMP = Glorious Perfection

My current set up is fully automated, and it's wonderful. I dump a bucket of brass into the Dillon hopper, power up, and it runs itself.

My first annealing experience was ~25yrs ago, using a torch in the dark and tipping cases over in a pan of water. I've done the deep-socket and hand drill thing too. My first automated annealer was a few years later which I built after seeing a Benchsource. I built an Annealeez clone, then bought a Giraud to feed a homemade induction coil like an Annie, tried salt bath and lead pot annealing, then eventually bought my AMP. If things go according to plan, I'll buy another AMP this summer.

Never used one, but think it would be beneficial.

There are a lot of claims about annealing and a lot of debate, but after 25 years, I know annealing enables 2 things, and everything else is largely conjecture:

1) Enables case forming (and resetting of neck/shoulder work hardening after case forming)

2) Resets case hardness to improve consistency between sequential firings of cases (aka, 12x fired brass will behave more like virgin brass if annealed)

There's a bit of conjecture about brass life improvement, and a LOT more about improved precision. I generally see most brands of brass start misbehaving pretty significantly by 7-8 firings (some as low as 5x), meaning the seating pressure has increased substantially, springback is becoming an obvious issue for sizing, and neck tension has gone sideways, and most casual shooters aren't taking precision rifle brass to 8 firings anyway, so it becomes kind of moot for most folks. But certainly, if you're taking brass past 10 firings (non-magnums), shoulder splits will eventually be part of your life unless you anneal. Precision, in general, isn't notably improved within a given lot of brass at a given firing - as I KNOW I can load firing-sorted brass to single digit SD's and shoot groups in the 1's and 2's, as small as I ever shoot with anything up to around 7-8 firings. Some might make it farther, and again, some might slip by 5. But if I'm loading mixed firing-count brass, I also KNOW that once fired brass does not respond the same as 10x fired brass when sized and seated, so primary ignition becomes variable, and results on target and across the chrony become variable. Annealing can bring that mixed-lot of brass to a common state (*Note - this is NOT meant to be read as mixed headstamp brass, or mixed lots, but ONLY referring to unification of brass from the same lot, same brand, same headstamp brass which has been fired a different number of times).

Do you annealing before resizing or after resizing?

Anneal before sizing and expanding.

I will be converting 223 in to 300 Blackout, would I annealing before resizing or after I resize the cases.

Anneal before AND after case forming, before final sizing and expanding.

On my regulat cases, do you annealing after every shot,

Annealing every other shot,

Or after a few shots.

I anneal every firing. Watching seating pressure on a 21st Century Hydropress, I see changes in seating pressure with every firing, meaning my neck tension and bullet grip by the neck are changing every firing if I don't anneal every firing - meaning my primary ignition is changing with every firing if I don't anneal.

![20230209_160347[1].jpg](/data/attachments/1133/1133018-11af1e6aab3ecd5850f20921e589c2df.jpg)