Great feedback and criticism guys, I really appreciate it! Keep it coming please.

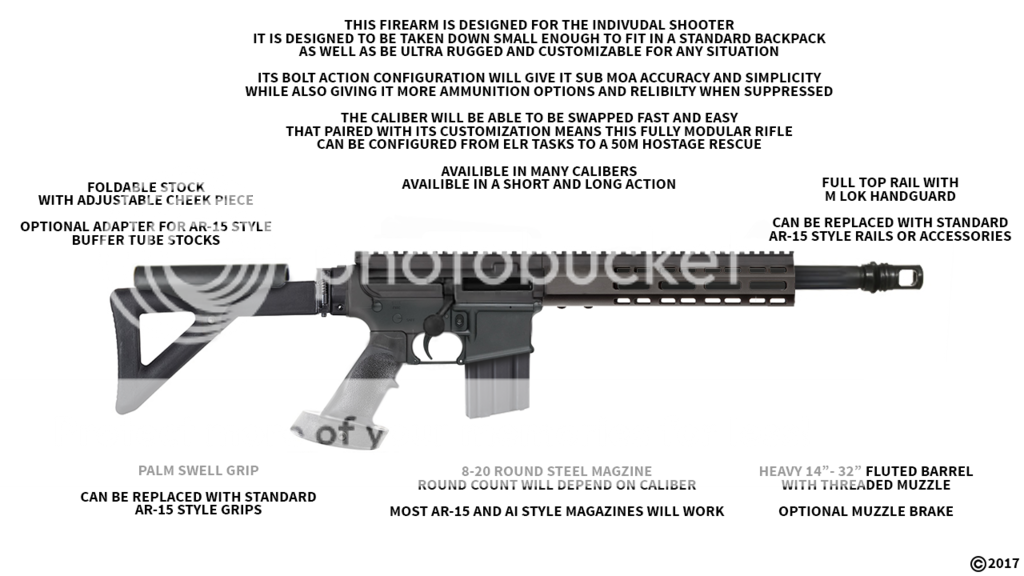

There's no doubt it looks like a RPR, but the RPR is based on the AR-10/15. As is mine, so that's kind of a given. However the RPR won't have many things that I want on my design such as:

The ability to change the caliber in the field. The RPR requires a vice and specialized tools. My gun will have a quick change systems such as those found on $5,000+ military orientated rifles where the barrel can be swapped in minutes with hand tools.

The RPR is only available in a few calibers, my gun will have 10+ in short and long action, including magnum rounds which the RPR doesn't have.

The RPR comes off as an AR style rifle that can use AR parts, but in reality some parts don't mesh with it well.

No offense to Ruger they made a great rifle, but the RPR is just a gun in the shape of a AR, this is pretty much an AR. So it will have much more options, i don't think the AR market is going anywhere for a long time, so why not embrace it and give people a rifle they can use that box of old AR parts on.

Why a bolt action design and not a semiauto traditional gas operation?

Better accuracy and stronger lockup.

A semi auto system simply wouldn't work for a modular quick change caliber system. You'd have to worry about the cartridge not having enough power to cycle the gun, or worry that there's to much power and the gun cycles to fast causing jams and damage to the rifle. Plus subsonic ammunition is almost always likely to cause problems paired with the increased sound of having a gas porting system makes the bolt action design far superior in this application.

Don't get it wrong, the gun shown is not a DMR rifle at all, this is designed for snipers purely. The one in the image configured is simply an example of the many variations it can be in. If i showed a .300 Win Mag with a 28" barrel I think there would be less confusion of the role of this design. The one shown is more configured for 50-300m engagements in close urban settings. The barrel length allows it to be concealed in a backpack and easy to maneuvered in doors.

Am I late to the party? Yes maybe, however in my research I didn't find a single bolt action AR-15 style rifle. Well there were ones in .50 BMG but I think that's a bit ludicrous and does not encroach on the market I'm aiming for at all. And although business wise it makes sense to build these as uppers that drop into an AR lower, I actually envisioned them as a more one piece receiver, caliber would be changed through the barrel nut not by replacing the upper. There's a reason for this, simply AR's have to much extra stuff not needed on a bolt action, plus if it's a one piece design the rigidity and vibration harmonics will be incredible.

Many would think an AR-15 style receiver bolt action would be less accurate and more complicated then a traditional hunting style gun such as the Remington 700. That couldn't be further from the truth, almost all precision rifles now days are moving on from the traditional design to a once piece chassis. This is because it removes all variables and essentially makes the firearm a 1 piece design rather than a 2 piece design. With traditional receivers that are bolted to a stock, things like flex and bedding and tension are a huge issue, there has been testing done that shows even having the screws 5 in/lbs to loose or tight can double group sizes. This adds up to a gun that is always changing zero and group size. The first use of a moncore design in a bolt action I can think of is the AI L96, It had its stock essentially welded to the barreled action giving it great accuracy. That is why I think my rifle design offers more than just throwing a Remington 700 in a aluminum chassis.

Now it's not all smooth sailing, I'm having a very hard time designing a sturdy smooth compact bolt, when designing a gun you really can only pick one of those 3. The issue with a small bolt is that there's a big crevice behind it where a bunch of mud can get and jam the action. Guns like the RPR and MRAD do away with that issue by making the bolt unnecessarily long to fill that area. The 2nd issue is the magazines. I originally said it will take AI and AR mags but I might have to retract that statement. The magazines need to be somehow fully adjustable to be able to feed any cartridge on the spectrum, I'm either thinking of making removable inserts in the magazines for different calibers, or making the inside dimensions of the magazine adjustable. My goal is to have this gun be able to be swapped to a different cartridge in less than 5 mins with just an allen key.

I know i am not innovating much at all, and that my rifle isn't the best at anything, but i just want it to be an extremely durable, precise, jack of all trades. Kind of like a smaller way more affordable Remington MSR.

I'm going to make a V2 rendering after I get a bit more feedback, this particular one was made in just a few hours and is just roughly what I want it to look like, many things will change.

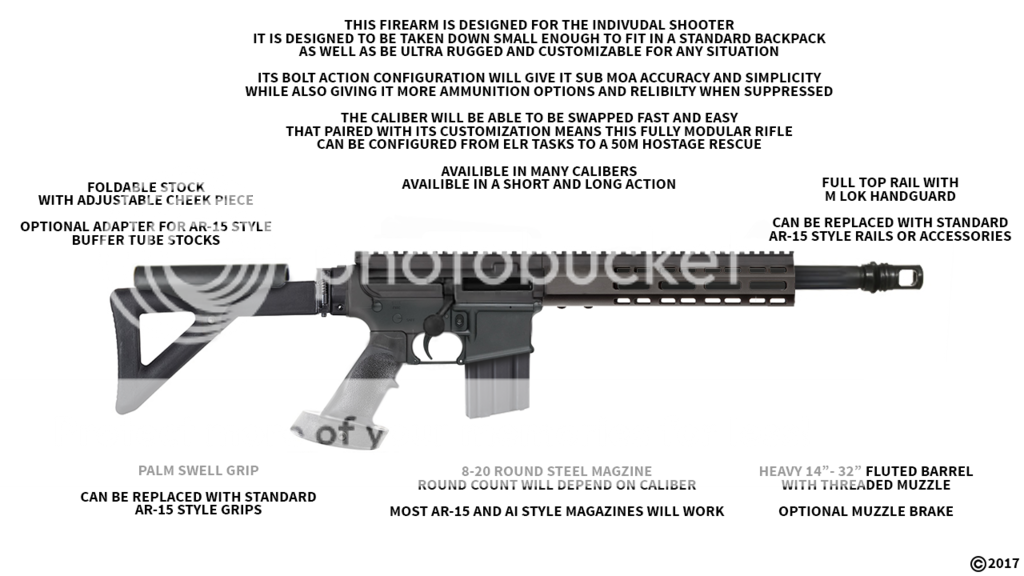

Thanks for reading, here are some examples on just how much the gun changes in the hands of the individual person. All parts are commonly found AR-15 accessories. Also a glimpse on how a long action may look.

You could even design the locking mechanism to where it was automatically disengaged by simply pulling straight back on the bolt handle.

You could even design the locking mechanism to where it was automatically disengaged by simply pulling straight back on the bolt handle.