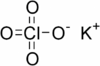

I don't disagree that all of the sub's contain the potassium perchlorate that can cause corrosion.

There is this 1st hand eyewitness testimony from Toby Bridges.

He states:

".... Just a month or so before this was written, I completed a test conducted with two .50 caliber No. 209 primer ignition in-line rifles, a

Traditions Vortek StrikerFire LDR and a

CVA Accura V2 LR, to see how many rounds could be fired before the bores had to be cleaned to maintain accuracy. This test began in January 2017.

I concluded the test on January 15, 2018. During basically that one year period, the

Traditions rifle had

482 rounds fired through it … the

CVA rifle had logged

493 shots during the same period. Neither of these rifles had a single cleaning patch pushed through the bore, and both were still consistently producing 1- to 1 ½-inch hundred yard groups. Both rifles cleaned up with a couple of

Blackhorn 209 Solvent dampened patches … a few dozen strokes with a .50 caliber bronze wire bore brush … a couple of more solvent dampened patches … a dry patch … and a lightly lubed patch. Both bores looked like new.

(Note: Primer carbon fouling was cleaned from the breech plugs every 150 shots.)....."

Our Side of the Blackhorn 209 Story by Toby Bridge --->>> http://namlhunt.com/bh209anniversary.html

*Note the warnings on the BH 209 label, always clean your gun as soon as possible after using BH 209 powder.

We can only speculate about how this can be true.

Perhaps there's a type of rust inhibitor that's built-in to the BH 209 powder, one which leaves an oil based film on the interior of the bore.

Maybe that's why BH 209 requires a gun solvent to clean it.

It could be similar to how the ingredients in stainless steel react with oxygen to create a stable protective film that resists corrosion.

This page explains how the film which is only a few atomic particles thick greatly helps stainless steel to resist corrosion. --->>>

https://www.scientificamerican.com/article/why-doesnt-stainless-stee/#:~:text=Stainless steel remains stainless, or,amounts of nickel and molybdenum.