If you want to increase velocity without effecting peak chamber pressure, you can go to ET (electrothermal) or ETC (Electrothermal Chemical) rounds. This was covered in the book I sent you which tragically went MIA.

With current battery technology, ET and ATC guns are almost practical. Instead of a conventional propellant, and ET guns uses a plasma stimulated working fluid (like water) and an electric pulse which can match the pressure/time curve of the cartridge to that of the limit of the chamber, rather than the spike associated with chemical propellants. Hughes was demonstrating a modified M16 in the 1980s that fires an M193 projectile from a slightly modified 5.56 case with a velocity of almost 6,000 fps. Normally, the velocity of chemical weapons is limited to about 5,000 fps max due to the limit of how fast the gas can expand. Plasma stimulated working fluids don't suffer from this limit.

If that's too exotic, one might be able to modify the traveller change artillery design. The propellant is basically fixed to the base of the projectile, and functions as a rocket motor, accelerating the whole way down the barrel. This requires very specific propellant manufacture which is probably not cost effective in small arms.

If one uses self consuming cartridges (AKA caseless) you do gain some chamber volume, which will allow for more velocity for the same pressure, but that quickly becomes a case of diminishing returns.

Keep it simple.

Pick a true intermediate cartridge operating at reasonable pressure, and launch a decent bullet at reasonable velocity. You don't need anything else.

Keep in mind that 90% of all infantry rifle fire is at 300 yards or less, and the infantryman's ability to hit a target in combat drops to about zero at 500 yards.

Clearly, 308 is unnecessary, but 5.56 seem underpowered at anything over 150 yards from the stubby barrels now popular.

As noted previously, the 6.5 Grendel seems to be a move in the right direction, but with too much emphasis on 1000 yard performance vs the 7.62x51. It's own developers admit it was originally conceived as a target round.

The already mentioned 6.5x45 was meant as a compromise between 5.56x45 and 7.62x51.

6.5 is literally halfway between the tow other cartridges. Bullet weight would be about 108 gn, and velocity should be around 2750 fps - about the same as M80 ball, with a much lighter bullet. Recoil is on the upper end of manageable.

This performance is what marketing has said the 6.5 Grendel can do, but the Grendel is severely hampered by it's case - not enough taper, too short and too much shoulder angle. These problematical areas came about by relying on the 22 PPC case, which was designed to be a target cartridge.

In designing the 6.5x45, I tried to duplicate and slightly better the 6.5 Grendel performance-wise, while having a better case design - that is, one lending itself to automatic magazine and belt fed weapons and having desirable characteristics of a combat round - moderate body taper, a shallower shoulder angle, and reasonable diameter to length ratios (short rounds are note desirable in semi and auto weapons are the target user).

The AK has a well deserved reputation for reliability, and the characteristics of the M43 round certainly help that reliability. The fact the cartridge is almost conical and the chamber funnel-like help insure goo feeding, and excellent ejection after even models primary extraction. The taper does require extremely curved magazines, and is probably more than required. A little less taper makes for more manageable magazines and simpler disintegrating belt designs.

With the influx of 7.62 Czech rifles into the US, the excellent 7.62x45mm case is becoming available. It has the same head size as the Russian 7.62x39. Thanks to additional length, the case, when necked down to 6.5 still has more volume than the 6.5 Grendel, even when a fairly large case taper is used.

Because I like round numbers, I selected a case taper of 1 degree. The 5.56x45 and 7.62x51 have a taper of about 20 minutes of a degree, compared with the M43 7.62x39 with it's taper of 1.5 degrees.

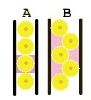

Here's an image of the 6.5x45

I originally tried to make the round fit in the M16 magazine, but this severely limited bullet selection. OAL on 5.56x45 is 2.260. I increased the OAL to 2.500, which allowed for a very wide range of bullets. This also fits in with out 'average' concept, as this OAL is between the 2.260 OAL of the 5.56 and the 2.800 OAL of 7.62x51.

Here's a comparison of several cartridges including the 6.5x45

Note the 6.5x42 is a variant of the 6.5x45 (based on the Czech 7.62x45) designed for the M16 magazine, but limited to lighter bullets only.

The advantage of the 6.5x45 is that it can accommodate lighter bullets for general infantry use, but still utilized the heavier, high BC bullets for long range DMR and sniper use. The cartridge does not generate excessive pressure, and in fact operates at a lower pressure but equal or more velocity than the 6.5 Grendel, while having a better shape for military small arms.

It does require a new platform, sitting between 223 and 308 caliber weapons. But by using a smaller diameter case, it is tilted towards the 5.56x45 family of weapons. Basically, and M16 sized weapon with an extra 0.240 inch is all that is required. Pressure is modest, at a max of 4050 barr.

The 6.5x45 is conceived as a general purpose round, replacing both 5.56x45 and 7.62x51. With heavier, modest BC bullets it will equal or even outperform 7.62x51 at long ranges. It has less power than 7.62x51 at short ranges, but outclasses 5.56x45 at all ranges. Lethality should be reasonable with a well designed bullet, and sectional density should make the 6.5 superior for barrier penetrations than the 5.56.

This is, of course, a reiteration of details already covered previously in this thread.

Basically, you can get something for nothing. More power (like the 7.62x51) means a heavier weapon and more recoil along with less ammo for the same basic load. 5.56 gives you a lighter weapon with more ammo and less recoil, but less power and a smaller lethality envelope.

6.5x45 merely splits the difference, attempting to be a good compromise all across the board.